Additive Manufacturing

Mastering Production with Markforged

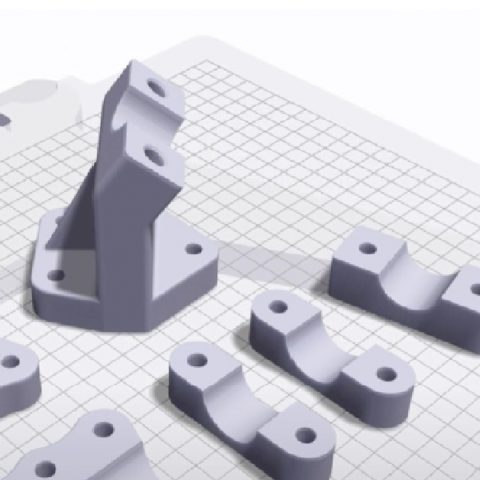

Recent advancements in additive manufacturing are transforming industrial production. This method, building objects layer by layer, offers a departure from traditional subtractive methods and provides unparalleled precision and design flexibility. Additive manufacturing reduces material waste and efficiently creates complex structures.

While often used interchangeably, additive manufacturing and 3D printing have distinct roles. Additive manufacturing is a broad category of building 3D objects by adding material, whereas 3D printing specifically refers to the precise layering technique within this category. This distinction not only expands manufacturing capabilities, enabling intricate geometries, but also opens up new possibilities in customisation and rapid prototyping.

Desktop Series

Mark Two™

Experience the award-winning difference of carbon fibre versatility. The Mark Two’s professional capabilities stem from the combination of Continuous Fiber Reinforcement (CFR) and a hardened extrusion system, effortlessly delivering robust parts with Onyx filament. Its precision-focused aluminium unibody design is augmented by the easy-to-maintain nature of the machine, featuring convenient component access and a remarkably repeatable print bed. When tackling your toughest designs, the Mark Two offers both uncompromising structural integrity and a simplified workflow that enhances productivity. Designed for those who demand reliability alongside precision, it seamlessly integrates into a professional workflow.

Onyx Pro™

Pushing the limits of what 3D printed parts can achieve, the Onyx Pro excels at complex structural needs. It brings professional Continuous Fiber Reinforcement (CFR) alongside a durable aluminium unibody frame, consistently crafting high-strength components. Unhindered by wear, a hardened extrusion system tirelessly works with Onyx filament for unparalleled results. Engineered for demanding industries, the Onyx Pro enables larger, intricate prints with confidence. For streamlined creation of cutting-edge parts, it provides hassle-free maintenance features and a precision-crafted print bed. Its power and meticulous detail empower bold visions in manufacturing and engineering.

Onyx One™

The Onyx One brings true power to your desktop, seamlessly blending advanced FFF capabilities and the outstanding resilience of Onyx filament. Don’t let its compact form factor fool you – this precision machine tackles ambitious projects with unwavering accuracy. From prototypes to end-use components, its accurate aluminium unibody delivers consistent quality. Effortless operation is key, from the bubble wear components to the swappable print head reliably sown with seeds for consistency. The Onyx One bridges the gap between desktop convenience and demanding composite printing requirements, unlocking new possibilities for designers and engineers. Discover the potential of desktop composite printing for innovative design and prototyping.

Industrial 3D Printers

FX10™

The FX10, Markforged’s latest innovation in industrial composite 3D printing, is engineered to excel where its predecessor, the X7, left a mark of success. It’s meticulously crafted to consistently deliver strong and precise parts with every print. Embodying a new modular design, the FX10 is poised for future enhancements and is equipped with print head-mounted optical sensors for real-time dimensional accuracy checks and overall device performance assessments. It streamlines the printing process with automatic calibration and easy material transitions, offering a user-friendly experience that reduces the reliance on specialised operators. The integrated Markforged software provides a seamless workflow from CAD to final print, facilitates part sharing within an organisation, and centralises fleet monitoring, all of which culminate in the FX10 being an indispensable asset for boosting manufacturing efficiency and profitability.

FX20™

The FX20™ is Markforged’s largest and most precise 3D printer. It features an 85L heated chamber and a flat vacuum bed, equipped with sophisticated motion control for fast and precise printing. The FX20™ introduces a turbo mode for quicker builds, a user-friendly 7-inch touchscreen for full operational control, automated calibration, and a material bay with moisture control to support up to four XL spools.

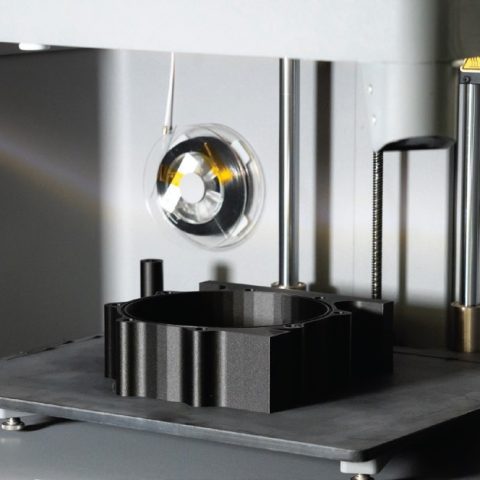

Metal X™ System

The Metal X™ introduces a revolutionary approach to metal printing. Utilizing metal powder bound in a plastic matrix, Markforged eliminates traditional safety risks associated with metal 3D printers, such as loose powder and lasers, making it safer for shop environments with minimal facility upgrades. This advanced FFF 3D printer method ensures the safety and accessibility of metal 3D printing.

X7™

The X7™ offers a blend of precision engineering, advanced sensors, and leading-edge software to deliver consistently accurate parts. It features a precision-machined gantry and a ground print bed for 10 µm repeatability, removable for easy maintenance. Designed to withstand wear from micro carbon fiber filled nylon filaments, the X7™ ensures sustained print quality over extensive use.

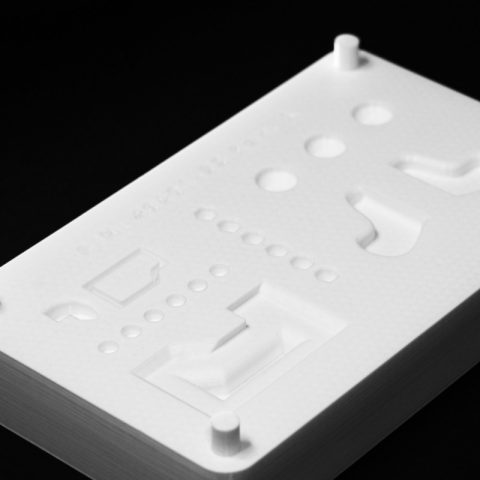

X3™

The X3™ specializes in printing engineering-grade plastic parts, leveraging the superior strength and stiffness of Onyx materials. It combines this with an advanced sensor suite for unmatched reliability and precision. The X3™ excels in producing parts with excellent surface finish and tight tolerances, ideal for integrating into production lines.

Materials

Metal

17-4PH Stainless Steel

Reduces lead times for metal tools, fixtures, and prototypes.

Copper

A conductive, ductile metal optimized for thermal and electrical operations.

Inconel 625

A nickel-based superalloy for strength and corrosion resistance at high temperatures.

H13 Tool Steel

A versatile hot work tool steel for manufacturing operations.

A2 and D2 Tool Steel

Cold work tool steels optimized for a wide variety of manufacturing applications.

Polymer

Onyx™

Micro carbon fiber filled nylon that forms the foundation of Markforged composite parts.

Onyx FR™

A certified UL 94 V-0 rated flame-retardant micro carbon fiber filled nylon.

Onyx ESD™

Stronger, stiffer, and ESD-resistant Onyx variant for industrial applications.

ULTEM™ 9085 Filament

An ultra high-performance PEI thermoplastic compatible with continuous carbon fiber.

Smooth TPU 95A

A rubber-like material that provides the ability to create flexible, impact-absorbent parts.

Precise PLA

A cost-effective thermoplastic for design validation.

Continuous Fiber

Carbon Fiber

The backbone of aluminum-strength composite parts.

Carbon Fiber FR

The backbone of flight-ready 3D printed composites.

Aramid Fiber (Kevlar®)

Tough, highly compliant Continuous Fiber for high-impact applications made with Dupont™ Kevlar® Fiber.

HSHT Fiberglass

Thermally resistant Continuous Fiber for strong parts in high-temperature environments.

Fiberglass

Entry-level Continuous Fiber for industrial applications.

Success Plans are available on all machine purchases and on a subscription basis

Let's Talk